Authorized Distributor

Sensor+

The Unified Monitoring System for PQSE Performance

(Process, Quality, Safety & Environment)

A next-generation, real-time and cost-effective monitoring system designed to enhance visibility, ensure regulatory compliance, and deliver unified oversight of PQSE parameters.

Request a DemoCapabilities

Key Features

Plug & Play

Installation and Go-live in hours

Modular & Scalable

Expandable system design

Real-Time Dashboard

Centralized monitoring

Threshold Alerts

Ensuring timely action

Flexible Config

Adaptable to any recipe or process

Batch & Equipment

Centric reports and analysis

Regulatory Compliance

CFR 21 Part 11 Compliant · NABL Certified · IP65 Certified

System Architecture

How Sensor+ Works

From sensors on the factory floor to real-time dashboards — a seamless, wireless data pipeline.

Hub-Reactor Setup

Factory Floor

STEP 1

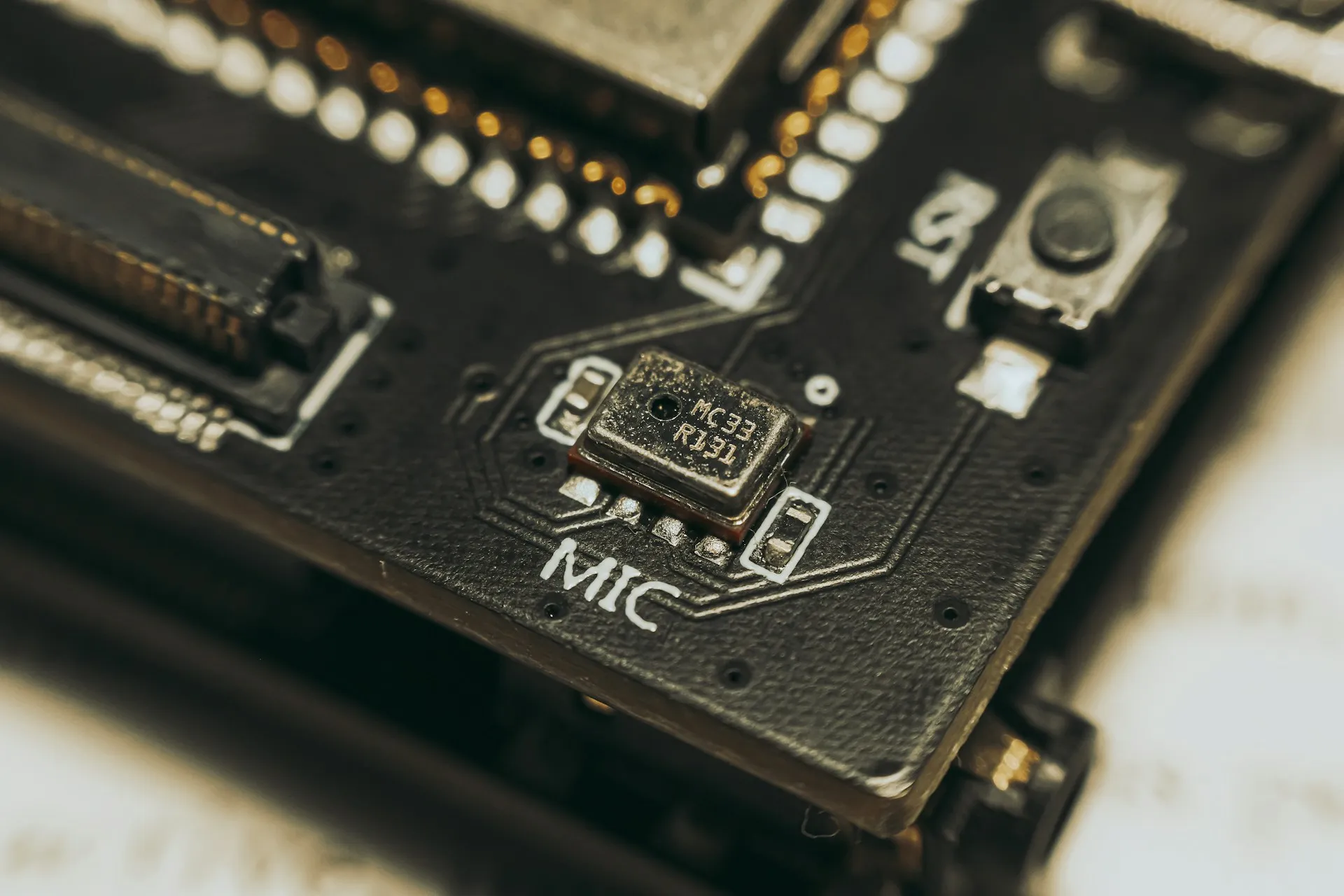

Sensor Integration

Sensors attach directly to reactors and process utilities.

STEP 2

Local RF Hub Collection

Multi-sensor values are captured and transmitted wirelessly.

STEP 3

Edge Processing

Threshold logic, alarms, and preprocessing happen before gateway sync.

RF Bridge

< 200m range

Gateway

LAN Connected

STEP 4

Analytics Gateway

Gateway consolidates streams and serves data via LAN.

STEP 5

Dashboards & Alarms

Operators get live status, threshold alerts, and batch visibility.

| Equipment | Batch | Status |

|---|---|---|

| Reactor-002 | No Batch | |

| Batch-01 | Active |

Range

< 200m

Communication

RF Wireless

Network

LAN

PLC Required

No

Process Control

Process Operations Monitoring

Configurable Recipes

- • Multi-stage processes with setpoints, instructions, and QC checks

- • Cleaning operations

Operator-Guided Execution

- • Trigger-based stage transitions

- • Instruction & QC acknowledgment

- • Time-stamped batch actions (Start, pause, resume, terminate)

Full Traceability & Compliance

- • Equipment e-logs for process efficiency

- • Product / Recipe Records

- • e-batch / e-cleaning records

- • Deviation Reports

Illustrative Process Recipe - Stage 1

Visual Batch FlowSTEP 1

Start Batch

Initiate monitored run

STEP 2

Add Materials & Reaction

Instruction: Add Materials 1 & 2

Setpoint: Temp = 90

STEP 3

Tech Crystallization

Stage transition rule

Setpoint: Temp = 5

STEP 4

Charcoalization

QC Check

Discharge action

STEP 5

Batch Complete

Process closed & logged

STEP 1

Start Batch

STEP 2

Add Materials & Reaction

Setpoint: Temp = 90

STEP 3

Tech Crystallization

Setpoint: Temp = 5

STEP 4

Charcoalization

QC Check & Discharge

STEP 5

Batch Complete

Monitoring Capabilities

Equipment & Utilities Monitoring

Equipment Monitoring

Operational Parameters:

For equipment:

Reactor, Bio Reactor, Fermenter, Dryer, Laminar Airflow, Isolator, Autoclave, Granulator, Lyophilizer, Blender, Solvent Tank, Receiver, Storage Container

Clean Room Monitoring

AHU / HVAC Parameters:

- • Humidity

- • Temperature

- • Airborne Particle Count

- • Air Pressure Differential

Utilities Monitoring

- • Process Water / PW / WFI: TOC & Conductivity

- • Temperature: Brine, Chilled Water, Hot Water, Steam

- • Flow Meters: Rate & Volume

- • Level Indicators: Solvent, Generic Items

- • N2 Pressure, Steam Pressure, Vacuum monitoring

EHS

Environment & Safety Monitoring

Environmental Applications

Water / Liquid Effluent

Air Pollution Monitoring

Safety Applications

- ! LEL Detection - Flammable and poisonous gases

- ! Nitrogen Pressure - Monitoring in N2 lines for nitrogen blanket

- ! Solvent Storage Tanks - Temperature/Pressure monitoring to trigger venting

Versatile

Applications Across Industries

Pharmaceuticals

- APIs, Intermediates & Formulations

- Biopharmaceuticals / Biologics

- Biotechnology

Chemicals

- Specialty Chemicals & Fertilizers

- Agrochemicals & Industrial Gases

- Dyes, Pigments, Paints & Coatings

- Plastic, Polymers & Petrochemicals

- Rubber & Latex Industries

FMCG & Aqua

- Food & Beverages

- Personal Care

- Sea Food Processing

- Aqua Culture & Equipment

- Home Care & Packaged Foods

Manufacturing & Heavy

- Cement & Steel Industries

- Textile & Garments

- Leather & Footwear

- Glass, Ceramics & Mining

Environment & Safety

- Water Treatment Plants (ETP/STP/RO)

- Solid Waste Management

- Air Pollution Control Equipment

- Recycling & e-Waste Management

Comparison

Sensor+ vs. Traditional SCADA

| Feature | Sensor+ | Traditional SCADA |

|---|---|---|

| Installation Time | ~1 hour/reactor, no disruptions | Weeks to months, equipment downtime |

| Batch Awareness | Stage-wise threshold, dynamic config | Requires MES integration, scripting |

| Data Ownership | Local-first, highly secure, no cloud | Cloud/internet dependent |

| Adaptability | Easily adaptable to recipes/products | Significant customization needed |

| Integration Cost | No additional setup, minimal custom | High customization required |

| License Cost | No license cost | Multiple 3rd party licenses |

| Infrastructure | No additional infrastructure | High wiring, cabling, server cost |

The Advantage

One System, Total Visibility

A single platform for process, quality, safety, and strategic performance with plant-ready execution.

Process Monitoring Benefits

- Real-time tracking: temperature, pressure, vacuum, pH, flow

- Supports reactors, fermenters, dryers, isolators, autoclaves

- Batch-wise control across charging to discharge

- No PLC programming required for deployment

- Instant stage visibility for proactive operations

- Control-room integration with RF range up to ~200m

Quality Monitoring Benefits

- Cleanroom monitoring: temperature, humidity, particles, differential pressure

- Utility quality checks: TOC, conductivity, PW/WFI, steam, chilled water

- GMP-ready data logs for audits and documentation

- Cross-batch consistency tracking by equipment and stage

- Early deviation detection with threshold alarms

- Centralized QC/QA dashboard visibility

Safety & Environment Benefits

- LEL and toxic gas risk detection

- Automatic alerts for unsafe temperature/pressure conditions

- Venting triggers for solvent tanks and reactor events

- Air quality monitoring: PM, O3, SO2, NO2, AQI

- Water and effluent tracking: COD, BOD, TDS, TSS, turbidity

- Improved EHS compliance and audit readiness

Operational & Strategic Benefits

- Cost-effective alternative to traditional SCADA

- Faster deployment through local data logger architecture

- Scales across multiple units and industries

- Accelerates digital transformation in legacy plants

- Improves OEE with lower downtime and faster response

- Enables predictive maintenance with centralized analytics

- Strengthens compliance posture and inspection confidence

Brochure

Sensor+ Deck & Distribution Ecosystem

Access the full brochure and connect directly with the manufacturer and authorized distributor.

Download Brochure

Complete PDF includes introduction, applications across industries, and the full Sensor+ advantage matrix.

- • Introduction & architecture walkthrough

- • Applications and use-case coverage

- • Sensor+ vs SCADA comparison

Manufacturer

Growth Accelerator Technologies Pvt. Ltd.

Growth Accelerator Technologies Pvt. Ltd., 12-3/522, Srinagar Colony, Rampally, Hyderabad, Telangana 501301

1800 410 2424

indiasource.co info@gatlabs.coAuthorized Distributor

Hapto Pharmaceuticals Pvt. Ltd.

Flat No. 401, Soucha Marvel Apartment, Chaitanya Layout, Khajaguda, Hyderabad 500104

+91 90009 99842 / +91 79955 08222

haptopharma.com sarath@haptopharma.comCertification

Authorized Distributor Certificate

Official authorization from Growth Accelerator Technologies for distribution and promotion of Sensor+.

Ready to Transform Your Monitoring?

Contact us to schedule a demo or learn how Sensor+ can be deployed in your facility.

Manufactured by Growth Accelerator Technologies Pvt. Ltd. | Distributed by Hapto Pharmaceuticals Pvt. Ltd.